Design and development of a 24V LiFePO4 Battery Pack for High-Performance Electric Wheelchairs

Powerful and Efficient Solution for Electric Wheelchairs and Other 24V Devices

Introduction

In the realm of electric mobility, reliable and efficient energy storage solutions are

essential. This project presents the design and construction of a 24V LiFePO4 battery

pack,

specifically engineered to replace traditional lead-acid batteries commonly found in electric

wheelchairs. Unlike lead-acid batteries, which suffer from short life cycles, rapid

depreciation, and inefficiencies over time, LiFePO4 technology offers a

superior alternative

with enhanced durability, safety, and energy density.

Optimized for powering electric wheelchairs, this battery pack is also versatile enough to

support other compatible high-performance 24V devices. By integrating advanced

battery

management techniques such as active and passive balancing, this solution ensures consistent

performance, extended lifespan, and seamless compatibility with various applications. The

project underscores a commitment to engineering precision, sustainability, and practicality,

providing a long-lasting energy source for modern needs while addressing the shortcomings of

outdated battery technologies.

Overview of the Build

- Selecting high-quality 33140 LiFePO4 batteries for durability and reliability.

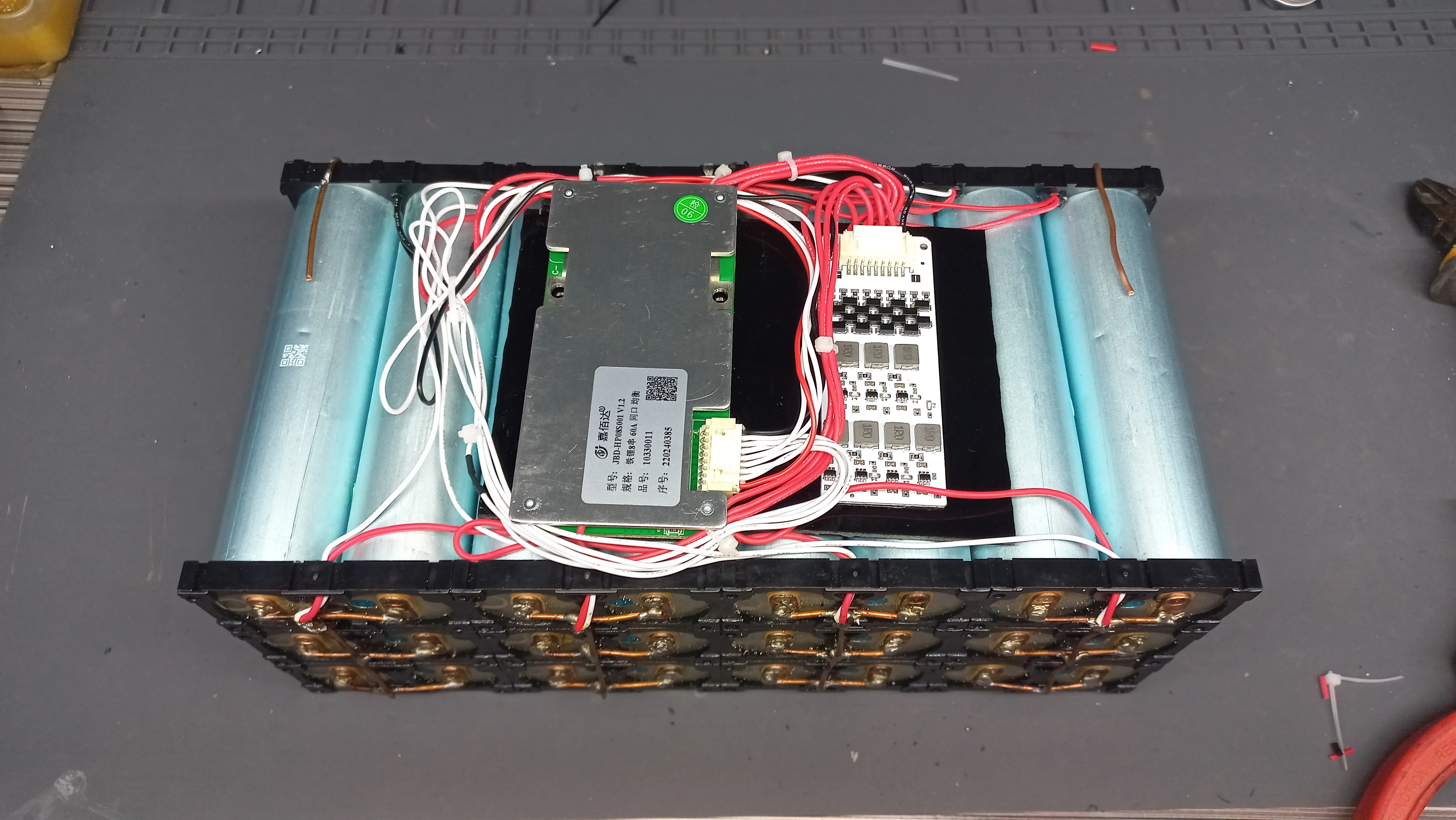

- Assembling the pack with a JBD 8S BMS for protection against overcharging, discharging, and short circuits.

- Integrating both active and passive balancers to optimize performance and longevity.

- Wiring with durable copper cables for stable electrical connections.

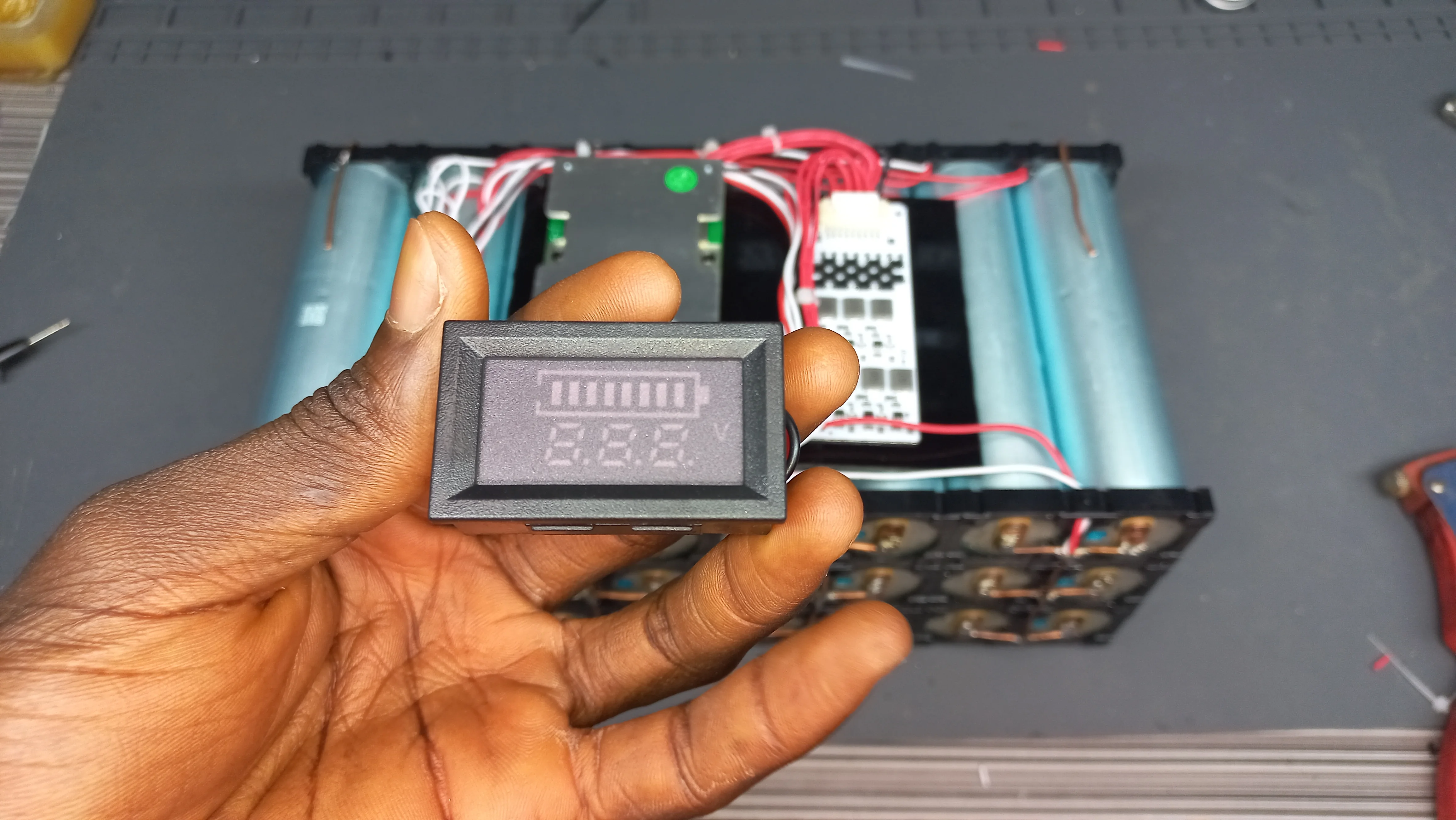

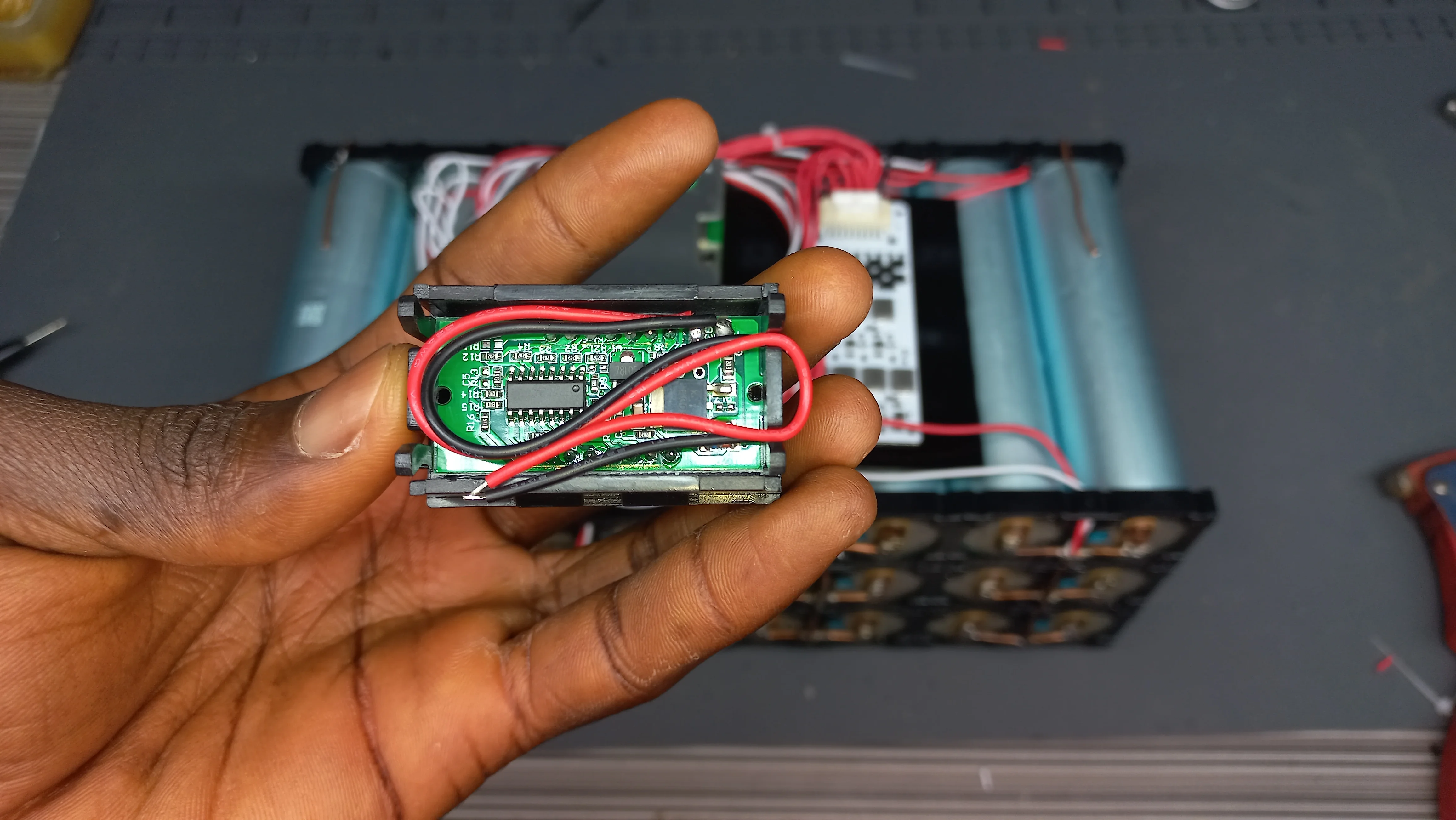

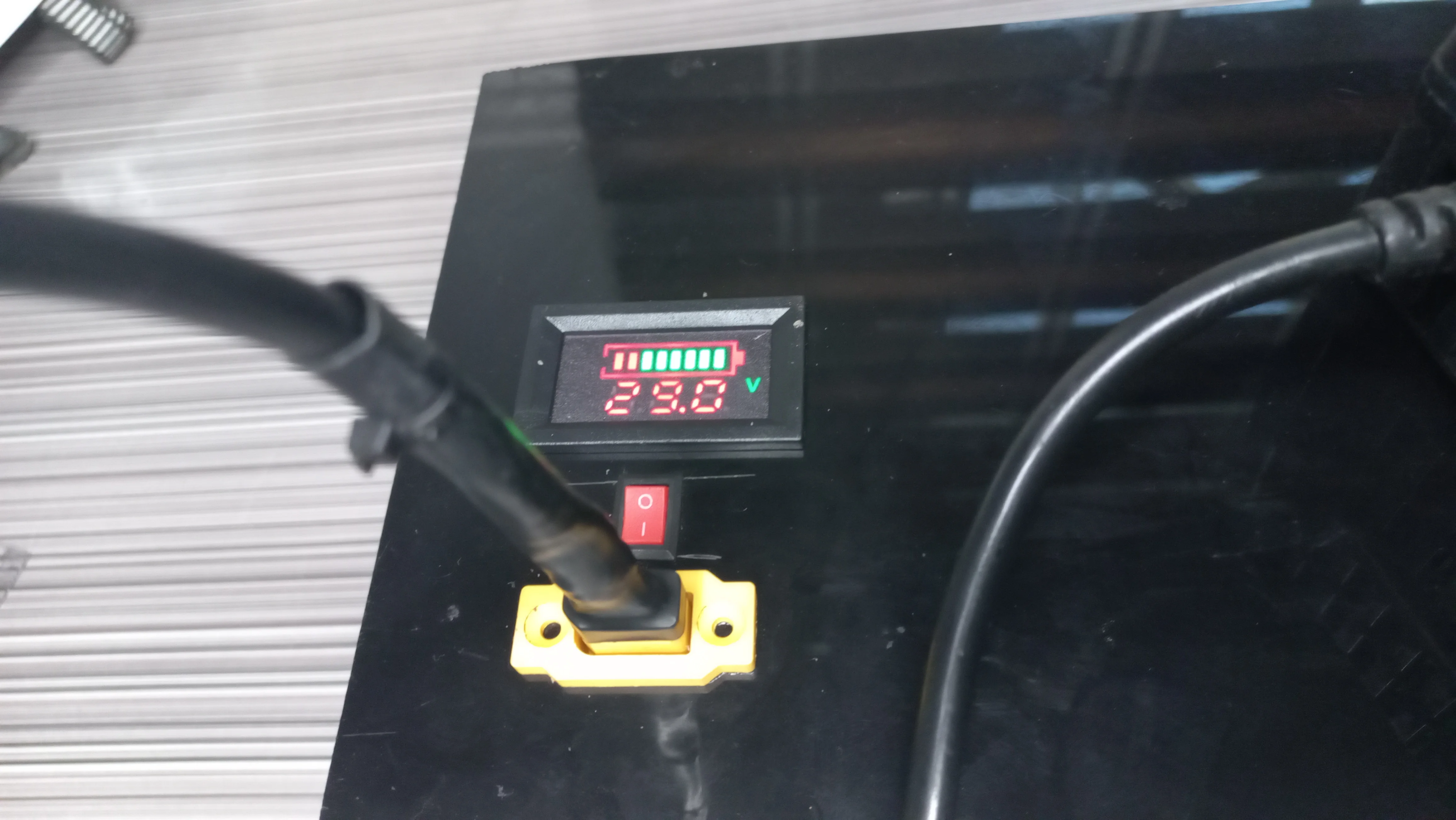

- Installing a charge and voltage display for real-time monitoring of the battery's status.

- Upgrading to XT-60 connectors for secure and reliable connections.

- Charging the battery.

- Testing the battery with the Electric wheelchair.

This project is perfect for those passionate about DIY battery projects or eager to learn about LiFePO4 technology.

Components/Materials Used

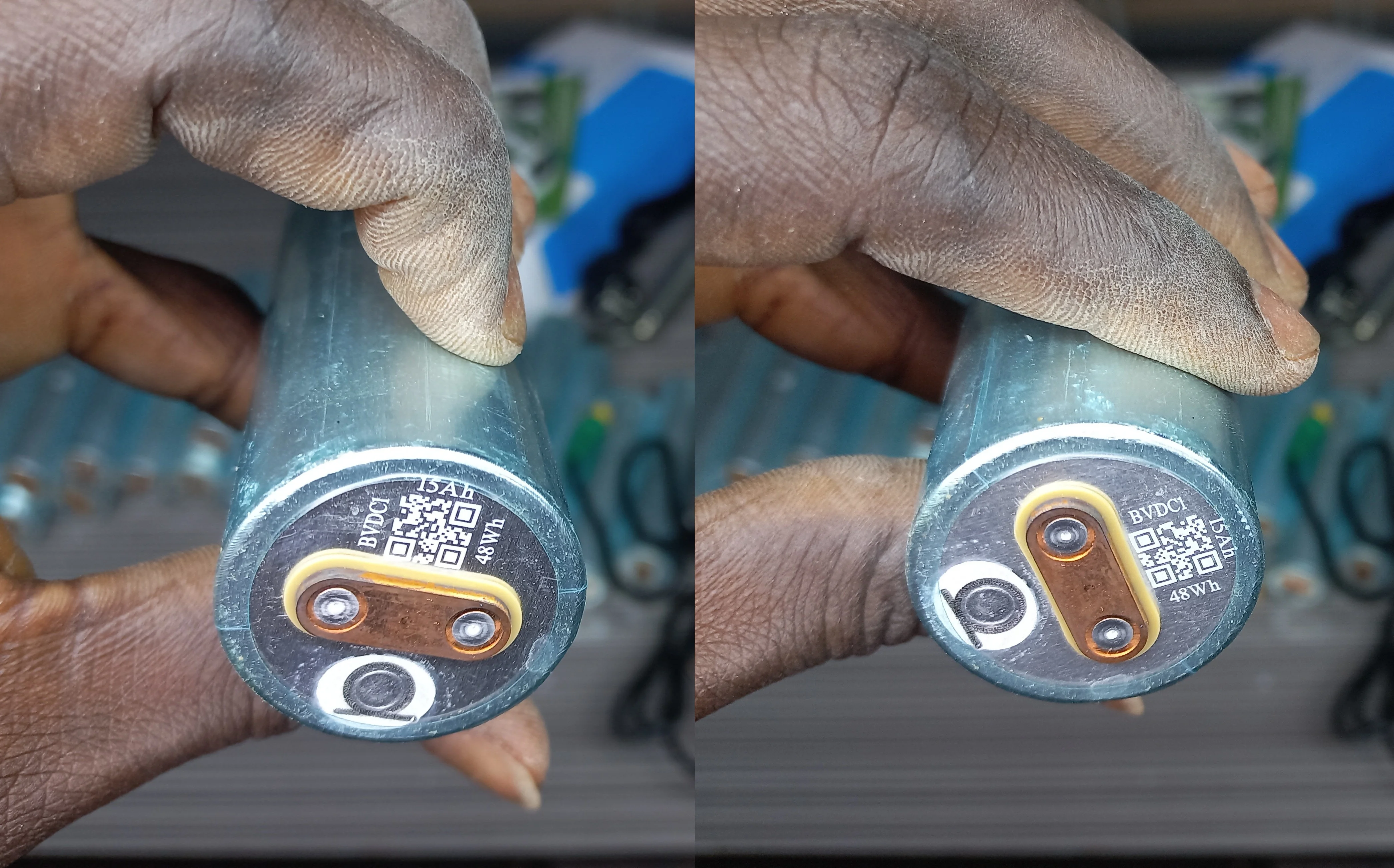

- 33140 LiFePO4 Batteries: 24 pieces (3.2V | 15Ah | 48Wh)

- JBD 8S BMS (Passive Balancer)

- 8S Active Balancer

- 4mm Stranded Copper Cable

- 4mm Single Core Copper Cable

- 24V Charge & Voltage Display

- XT-60 Connectors: 2 pieces (male and female)

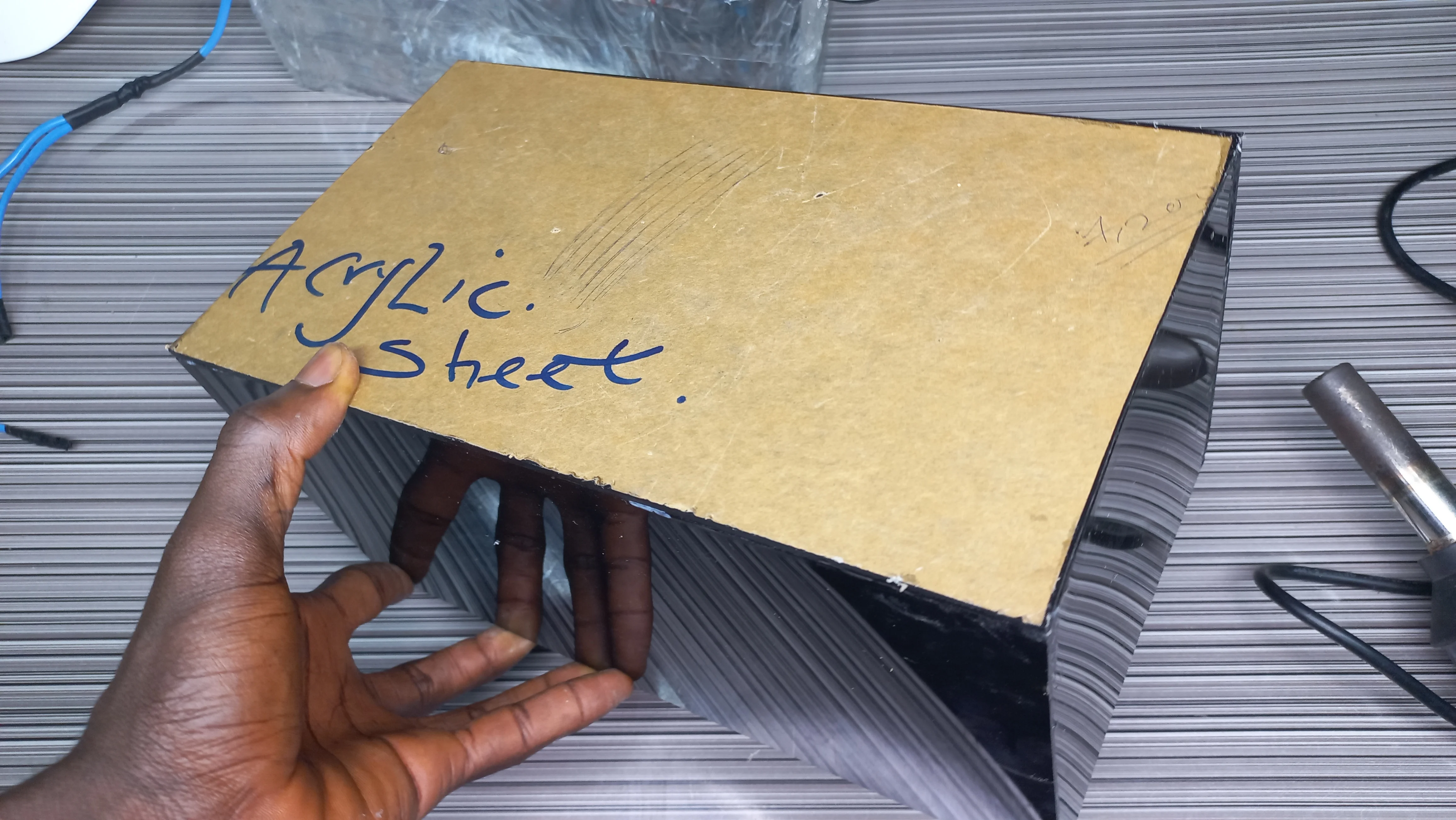

- Acrylic Sheets and Glue

- Soldering Iron (or Electric Arc Welder for Batteries)

- Multimeter

- Switch

- Various basic electrical and electronics engineering tools

Step-by-Step Process

1. Selecting Components

High-quality 33140 LiFePO4 cells were chosen for their durability, energy density, and safety. The JBD 8S BMS Passiive and Active Balancer were integrated for essential protection features, including overcurrent, overvoltage, and undervoltage safeguards.

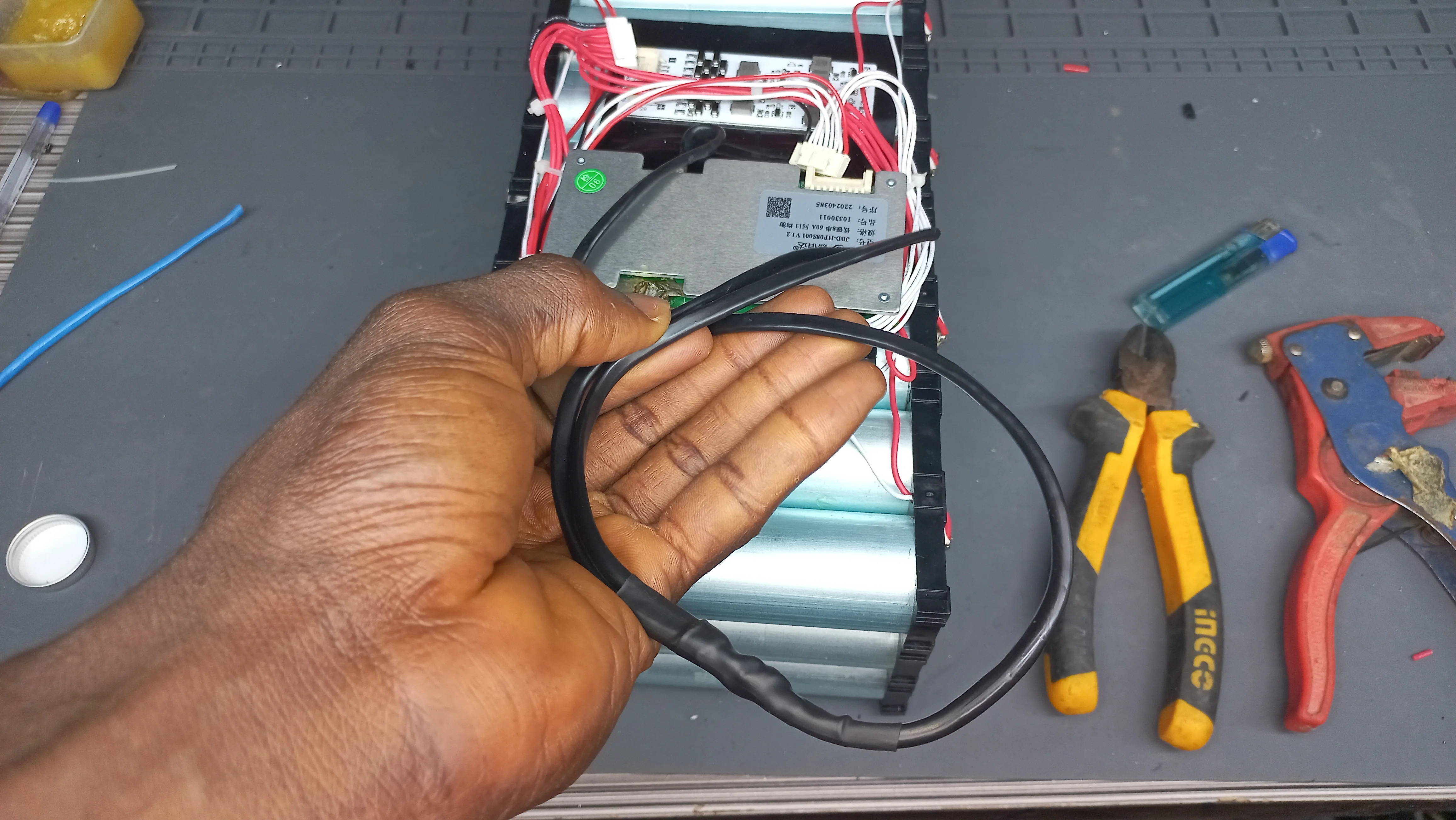

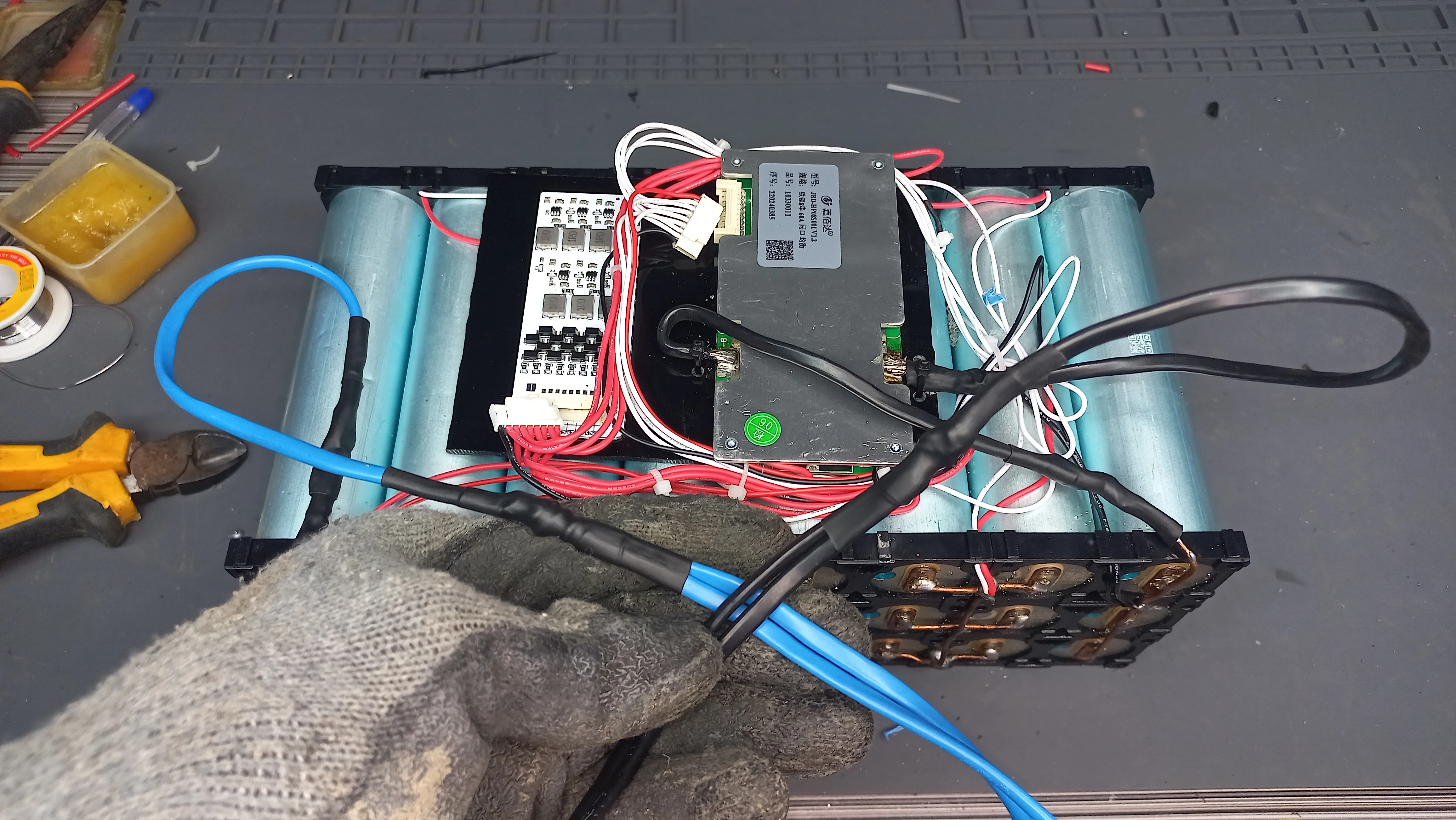

2. Assembling the Battery Pack

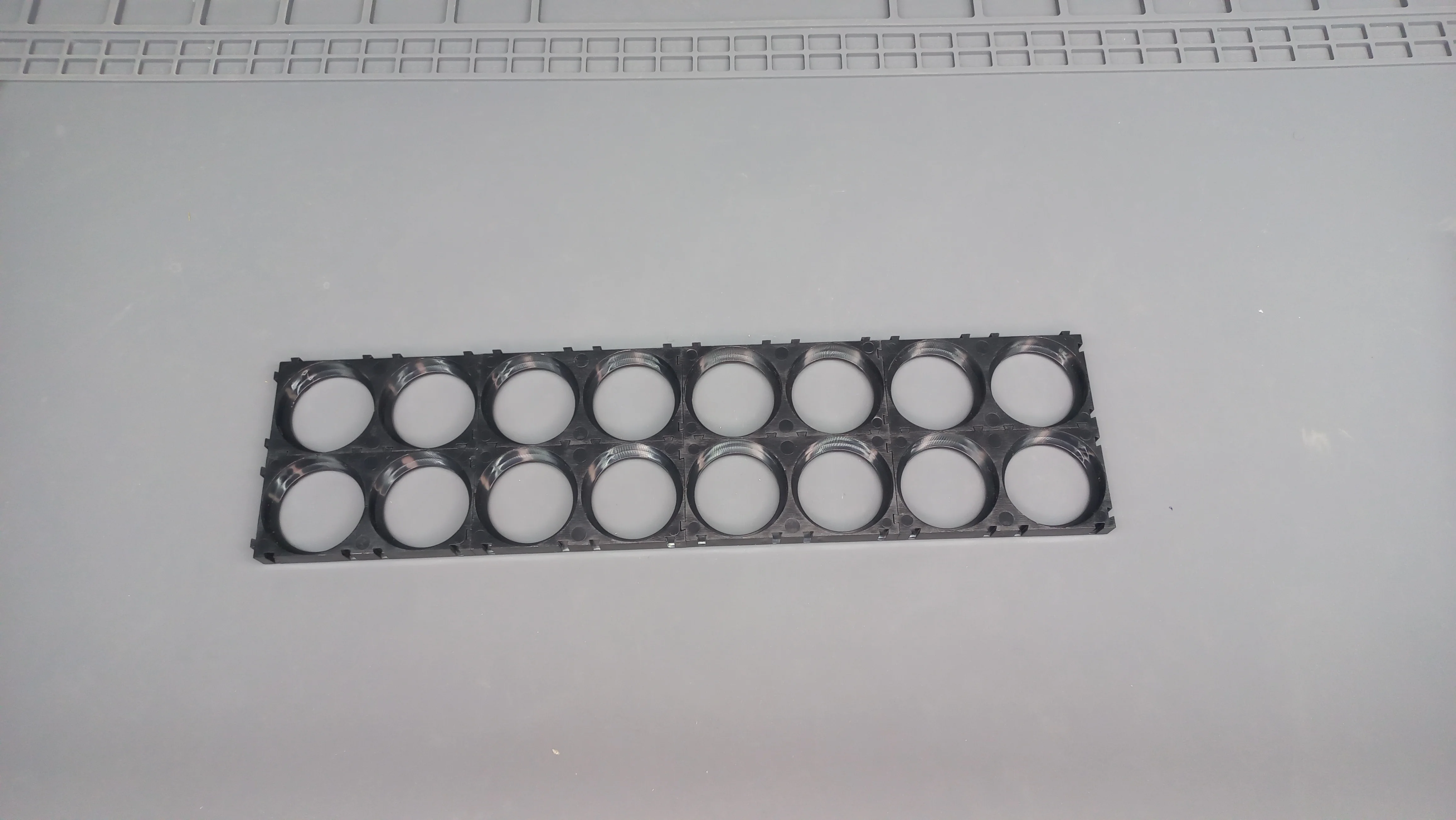

The cells were arranged in a series-parallel configuration, ensuring a 24V output.

- Active and Passive Balancers were installed to ensure uniform charge distribution.

- Soldering was used to connect the cells with durable copper cables.

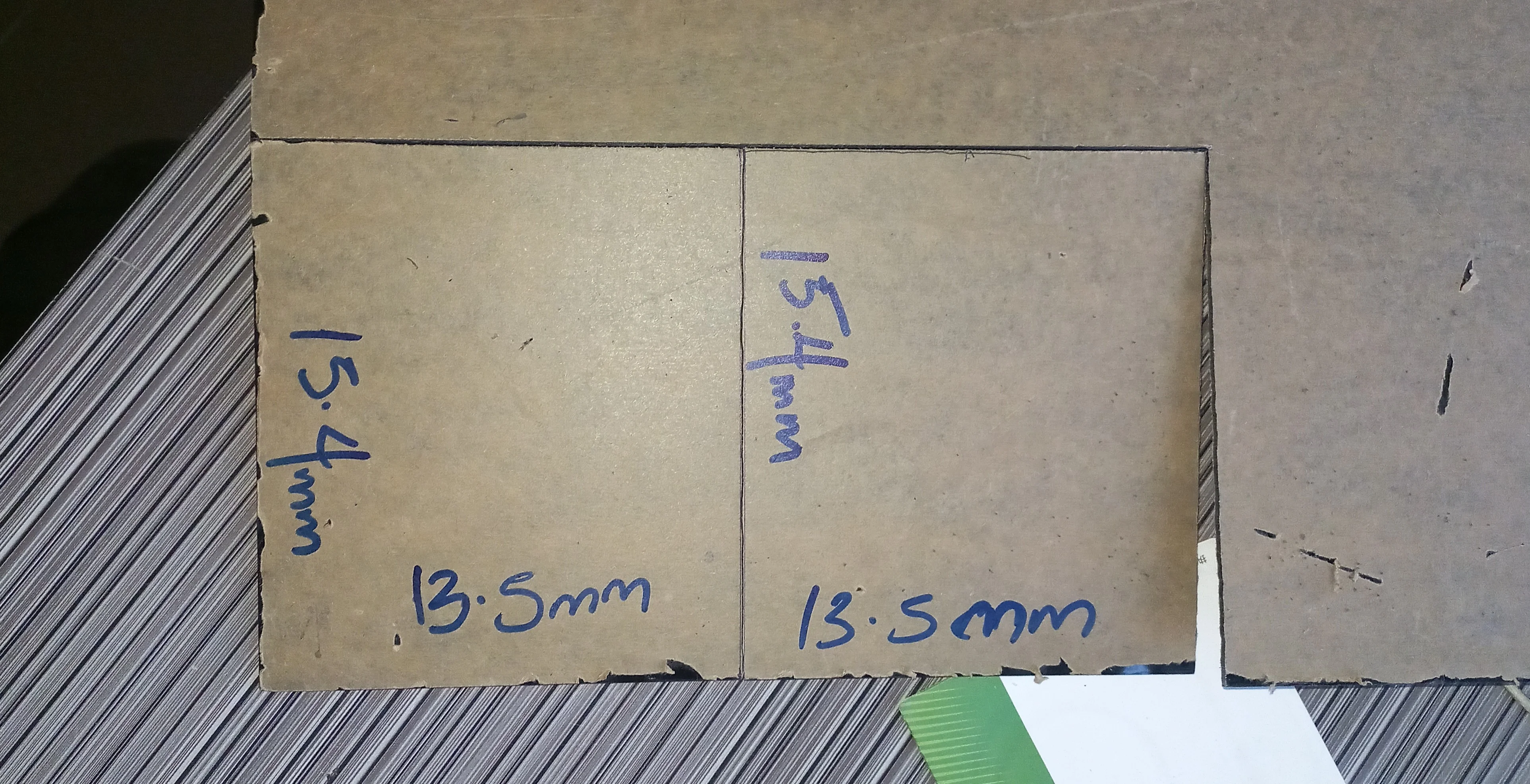

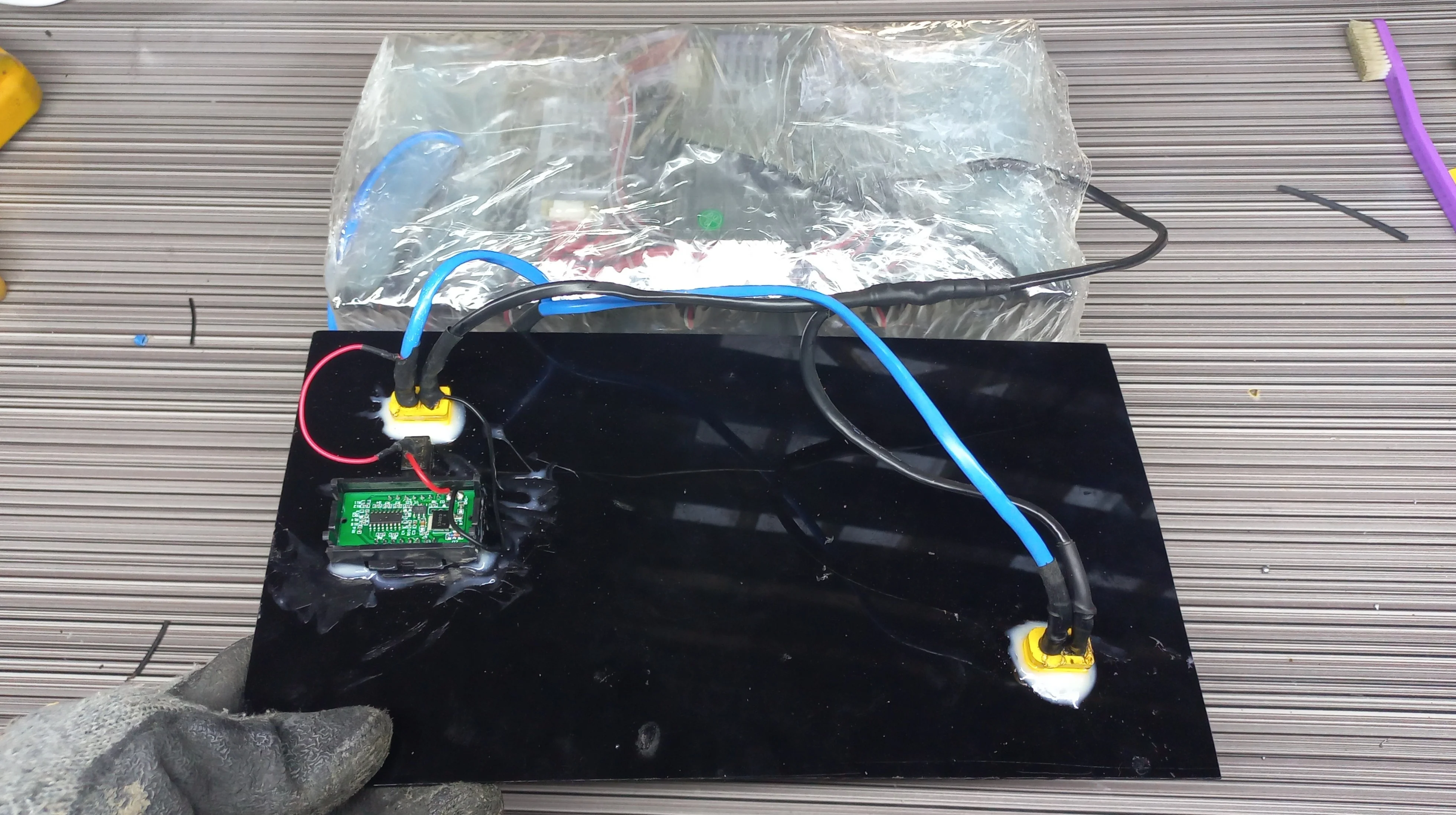

- Acrylic Sheet was engineered to fit the overall dimension of the battery pack.

Battery Holder Assembly

Battery Assembly

Battery Assembly

Assembled and Connected Cells

Assembled and Connected Cells

Acrylic Sheet Design

Acrylic Sheet Design

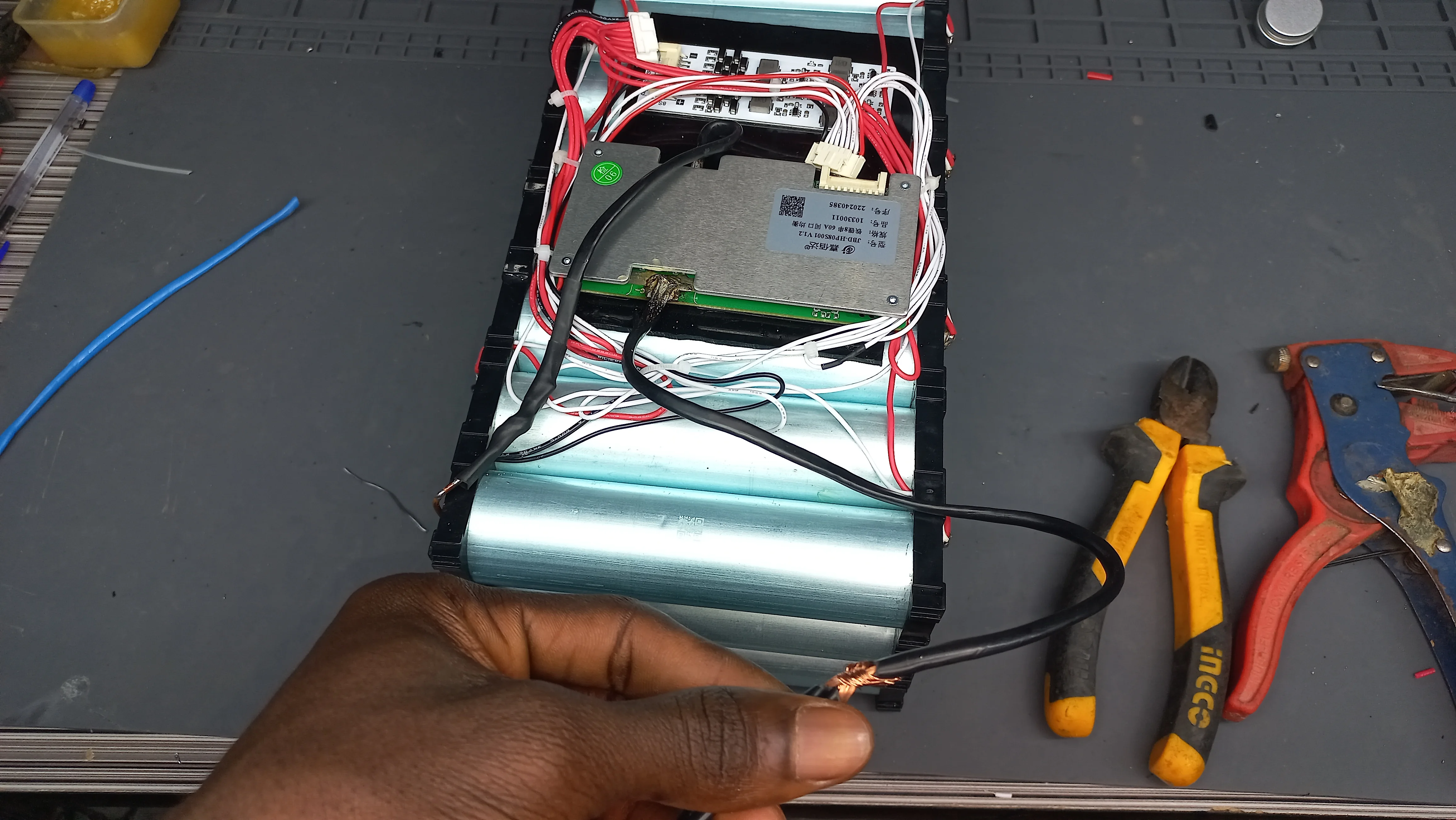

3. Wiring and Soldering

Durable 4mm stranded and single-core copper cables were used for internal connections.

- XT-60 connectors were added for robust input/output connections.

- The charge and voltage display was integrated to monitor the battery's status.

wiring and connector soldering

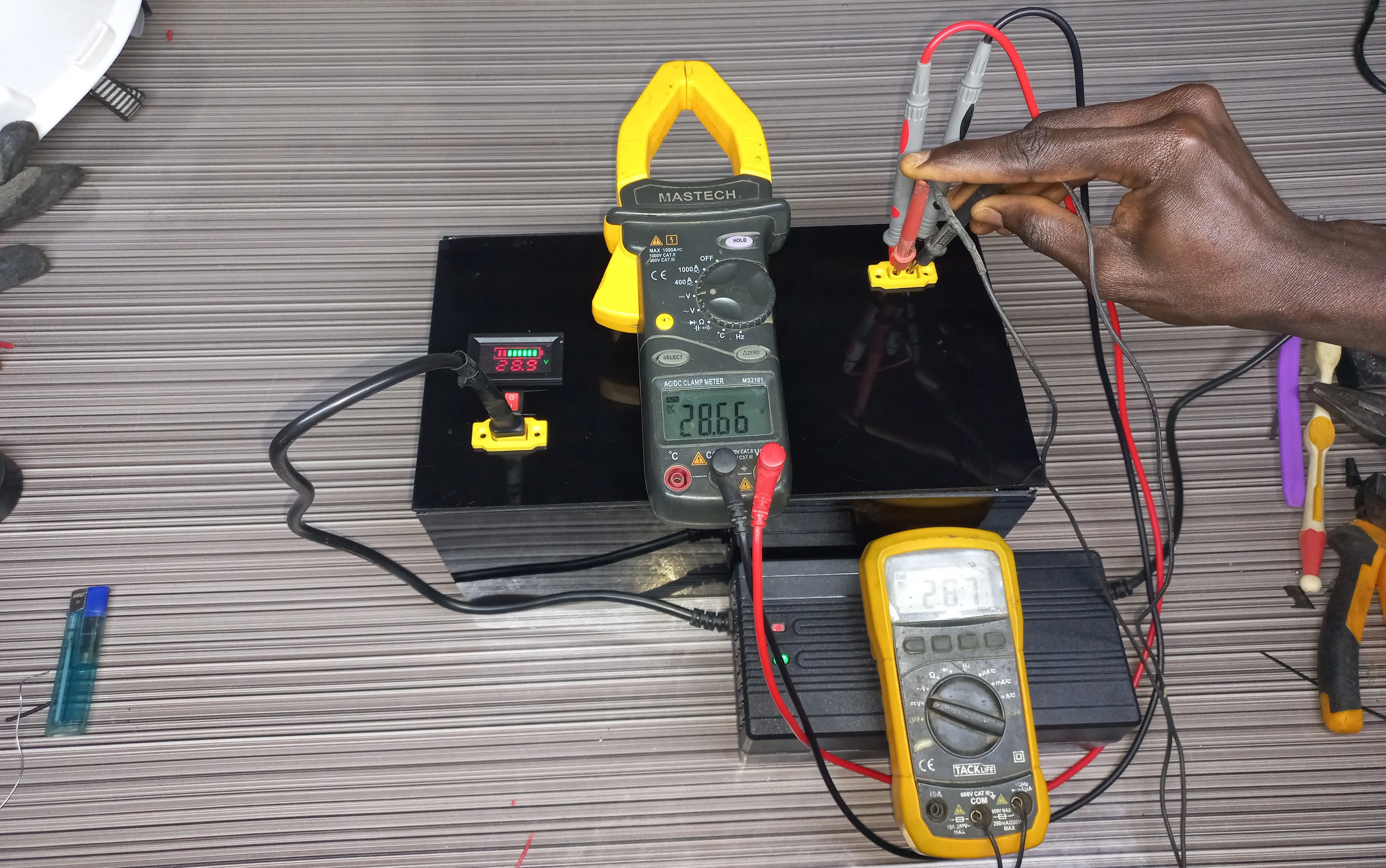

4. Charging the Battery

The assembled pack was connected to a suitable 24V LiFePO4 charger via the integrated XT-60 connectors.

- The JBD 8S BMS regulated the charging process, ensuring the cells were protected against overcharging.

- The charge and voltage display provided real-time feedback on the charging status, including percentage levels and whether the battery was "IN" (charging) or "OUT" (outputting).

- A full charge cycle was completed to verify that all cells were balanced and operating within their optimal voltage ranges.

- A 24V, 10A LiFePO4 battery charger was used to charge the system, providing a no-load output of 29.0V, which matches the battery's full charge voltage. This alignment ensures the battery is fully charged when it reaches 29.0V. LiFePO4 chargers are designed to balance the cells and prevent overcharging, often reducing current as the battery nears full capacity to protect its lifespan and maintain optimal performance.

Charging the battery

(The voltage was observed to reached 29.0V and this was exactly the output voltage from the

charger)

Note: There is a slight discrepancy in the readings shown below. The charging display shows

28.9V, while

my two multimeters show 28.66V and 28.7V respectively. This difference could be due to

variations in measurement

methods or equipment calibration

Below picture depicts the full charging voltage of the battery.

5. Testing and Integration

The battery was tested with a multimeter to ensure correct voltage and capacity. It was connected to an electric wheelchair to validate performance under real-world conditions.

Testing Setup and Final Integration with the Wheelchair

Battery's voltage before being charged

Connecting the wheelchair's input cable to the battery's output terminal and Driving the

Wheelchair

Connecting the wheelchair's input cable to the battery's output terminal and Driving the

Wheelchair

Performance Calculations and Analysis

This section details the performance and characteristics of the battery pack connected in an 8S3P configuration, highlighting voltage, capacity, energy, runtime, current draw, and charging time. These calculations provide a comprehensive understanding of the pack's capabilities and its adaptability for various load conditions.

Battery Specifications

- Cell Specifications:

- Voltage: 3.2V

- Capacity: 15Ah

- Energy: 48Wh

- Configuration:

- 8S (8 cells in series): Increases voltage.

- 3P (3 cells in parallel): Increases capacity.

Key Calculations

- Nominal Voltage:

V_total = 3.2V × 8 = 25.6V - Total Capacity:

C_total = 15Ah × 3 = 45Ah - Total Energy:

E_total = V_total × C_total = 25.6V × 45Ah = 1152Wh = 1.152kWh - Runtime Examples: (For a load consuming)

- 100W Load:

t = E_total / P_load = 1152Wh / 100W = 11.52 hours - 300W Load:

t = E_total / P_load = 1152Wh / 300W = 3.84 hours - 500W Load:

t = E_total / P_load = 1152Wh / 500W = 2.304 hours - Current Draw Examples: (For a load consuming)

- 100W Load:

I = P_load / V_total = 100W / 25.6V = 3.91A - 300W Load:

I = P_load / V_total = 300W / 25.6V = 11.72A - 500W Load:

I = P_load / V_total = 500W / 25.6V = 19.53A - Charging Time: (With a given charging current)

- 5A Charger:

t_charge = C_total / I_charge = 45Ah / 5A = 9 hours - 10A Charger (i used this charger):

t_charge = C_total / I_charge = 45Ah / 10A = 4.5 hours

Summary of Performance

- Voltage: 25.6V

- Capacity: 45Ah

- Energy: 1152Wh (1.152kWh)

- Runtime Examples:

- 11.52 hours for a 100W load.

- 3.84 hours for a 300W load.

- 2.304 hours for a 500W load.

- Charging Time:

- 9 hours with a 5A charger.

- 4.5 hours with a 10A charger.

Safety Considerations

- Always use proper protective equipment when handling batteries and electrical components.

- Double-check all connections to avoid short circuits and overheating.

- Monitor the battery during initial use to ensure safe operation.

Key Features of the Battery Pack

- Durability: LiFePO4 chemistry ensures longevity and resilience.

- Efficiency: Active and passive balancers optimize charge distribution.

- Safety: JBD 8S BMS protects against electrical hazards.

- Real-Time Monitoring: Voltage and charge display ensures transparency.

- Robust Connections: XT-60 connectors provide reliable connectivity.

What I Learned

- Advanced battery management system integration.

- Effective wiring and soldering techniques for high-performance applications.

- Real-world application of LiFePO4 technology in energy storage.

- Importance of safety and testing in DIY electrical projects.

Demonstration & Resources

This video provides a detailed walkthrough of the battery pack build, from unboxing the components to the final testing with the electric wheelchair. You can watch the embedded video below or click the link to view it on YouTube.

- YouTube Video: Watch the Full Build on YouTube

- GitHub Repository: Explore the circuit diagram and others

Future Enhancements

- Scaling the design for larger capacity requirements.

- Integration of a wireless monitoring module for remote status updates.

- Development of modular battery packs for easier maintenance and scalability.

Showcasing Myself and Expertise

Thank You for Visiting My Portfolio

I sincerely appreciate you taking the time to explore my portfolio and learn about my work and expertise. It is my hope that these projects and insights have demonstrated my passion for innovation, my technical skills, and my dedication to delivering impactful solutions.

If you have any questions, require further information, or wish to discuss potential collaborations, I would be delighted to connect. Please feel free to reach out via the Contact section. Your feedback and inquiries are highly valued and will be addressed promptly.

Thank you once again for your interest in my work. I look forward to the opportunity to collaborate and contribute meaningfully to your projects or organization. Together, let us innovate and achieve excellence.

Best regards,

Damilare Lekan, Adekeye.